Piston and Rod Pumps in the Oil and Gas Sector

What's the Difference?: Piston and Rod Pumps in the Oil and Gas Sector

In the field of oil and gas industry, pumps act as key components that facilitate the movement and transfer of fluids in various operational stages. Two common types of pumps, piston and rod pumps, play a key role in these processes. Understanding their differences, advantages and disadvantages is crucial to choosing the most appropriate one in this demanding sector.

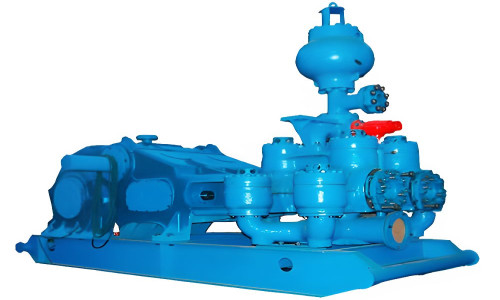

Piston pumps:

Piston pumps belong to volumetric hydraulic pumps that work on the principle of "compression" of liquid. The principle of their action is based on the creation of pressure in the liquid injected through a piston moving back and forth inside the cylinder. These types of pumps create high pressure at lower efficiencies than centrifugal pumps. Due to their construction, piston pumps are very simple, so they were introduced much earlier than centrifugal pumps. Currently, these pumps are widely used in production, especially where low efficiency is required at high pressures.

Usually, in reciprocating pumps, the output is not regular with respect to time. Piston pumps have different designs depending on their purpose, working conditions and properties of the liquid to be pumped. For example, they are divided into two types: piston and plunger. From the hydraulic point of view and the working process, piston and plunger pumps are identical. Their constructive difference is that they are useful in different cases of work. Thus, it is convenient to use plunger pumps at pressures over 10...20 MPa, and piston pumps at lower pressures.

Advantages of piston pumps:

High Pressure Handling: Reciprocating pumps excel at handling high pressure applications, making them suitable for special oil and gas operations.

Versatility: They can handle a variety of fluids, including those with higher viscosity or corrosiveness.

Control: Offers precise flow control essential for specific applications within industry.

Disadvantages of piston pumps:

Maintenance Requirements: Their complex design can often lead to more technical maintenance requirements, which can lead to longer operating times.

Initial cost: Typically these pumps require a higher initial investment than other types of pumps.

Piston pumps:

A deep well sump pump is the most common pumping equipment used in oil extraction. One of the main reasons for its wide application is that it is structurally relatively simple, convenient for the operation of wells with low and medium productivity. It is possible to lift up to 500 m3 of liquid to the surface of the earth with a well rod pump.

The working principle of the depth pump is as follows: when the plunger goes up, the striker is closed by the pressure of the liquid column on the valve. The suction valve is opened due to the pressure of the liquid column that penetrates the depth of the valve, and the oil enters the pump - the suction process takes place.

When the plunger goes down, the reverse process takes place, that is, the impact valve opens and the suction valve closes. As a result, the liquid level in the pump pipes rises to the wellhead. In the subsequent operation of the pump, the liquid is raised to the surface. The submersible pump is in difficult conditions during operation. The efficiency of the pump depends on many factors, for example, the elastic elongation of the rods and pipes, the shape of the pipes, the value of the pressure drop in the gap between the cylinder and the plunger, the amount of sand and gas in the suction liquid, and the intensity of deposition of paraffin on the pipes.

Advantages of piston pumps:

Durability: Renowned for their durability, piston pumps withstand harsh weather conditions and corrosive fluids, making them suitable for demanding oil and gas environments.

Low Maintenance: In general, piston pumps require less maintenance, resulting in less downtime.

Efficiency: Especially efficient in handling higher volumes of liquid at lower speeds.

Disadvantages of piston pumps:

Limited Field of Use: There may be limitations in working with specific fluid types or bases, which may affect their suitability for certain applications.

Flow Control: Compared to reciprocating pumps, piston pumps can have less precise control over flow rates and pressures.

Both piston and piston pumps offer different advantages and solutions in the oil and gas sector. While reciprocating pumps handle high pressure and provide versatility, piston pumps can excel in terms of durability and efficiency. The choice between them depends significantly on the specific operational requirements, fluid characteristics and also the general project requirements in the oil and gas industry.

Understanding these differences will help you select the most appropriate pump type to ensure optimal performance and reliability in complex oil and gas operations. As Polad Techno, we can perform detailed calculations for your gas and oil industry projects and provide you with detailed information about the equipment you need.